Description

First of all and before anything else it is necessary to have clear the dimensions of the screw that must be automatically fed and the application point in which it must be screwed.

We suggest to follow and complete the specific form for this step

Depending on the length of the screw or the environment, it is therefore necessary (sometimes forced by the dimensions of the screw itself) to select the type of power supply to be used (1) tilting blade systems for maximum M6 screws with stem length within 25 mm Systems vibro cup for screws with longer and longer dimensions.

The selection of the control box (2) is important and fundamental for the management of the automatism in applications for automatic use or if there is no control logic integrated in the line or familiar with the PLC systems, two versions are available. for single station management and a more complete one with PROFINET interface possibility of multiple management. The selection of the control box is not necessary for applications of auto systems powered by manual use

The qualitative part of the tightening is normally determined predominantly by the type of motorization that one intends to adopt; it is important, depending on the criticality of the joint and the production rate, to select the correct motorization (3)

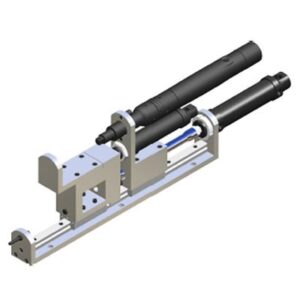

For all automatic and manual applications it is important to define the strokes required for use (automation use) and the type of drive (manual use). (4) The VT78 slides are equipped with a double-stroke system with pneumatic movement by cylinders, the standard strokes are 50mm for approach and 80 mm for tightening, but variations of the strokes are possible depending on each specific requirement. For applications for manual use, the type of drive required must be selected if, with the self-advancing system (by pressing the start lever of the screwer, the system through an internal piston keeps the screw pressed) or by pressure actuation where the start is generated by the pressure of the operator towards the tightening point.

Finally (5) the selection of the head is normally a function of the type of screw and of the application point; in the case of automatic stations the selection can be made by selecting the same among those shown in the table with or without screw retention pipe; while for the heads related to plants for manual use this selection is already done by us according to the information received by adopting the head which guarantees the best performance.