Description

The MD or AD-Series is a durable torque and automation control system engineered for precise, accurate and repeatable torque control. The high performance torque fastening system by Mountz allows manufacturers to optimize the assembly area, reduce labor costs and increase productivity. The DC control tool delivers cost savings and quality benefits through useful features such as digitally adjustable torque setting, variable torque and speed control, multiple I/O options for integration with PLC and other line control techniques. A Windows-based software package that can customize each fastening application is included with the product.

The torque control system features error-proofing capabilities and screw counting. Multiple fastening strategies can be implemented for sensitive and/or difficult assembly joints. The system increases productivity as one tool can be programmed to do the job of multiple conventional tools; saving time, maintenance cost, space and training.

Strengths

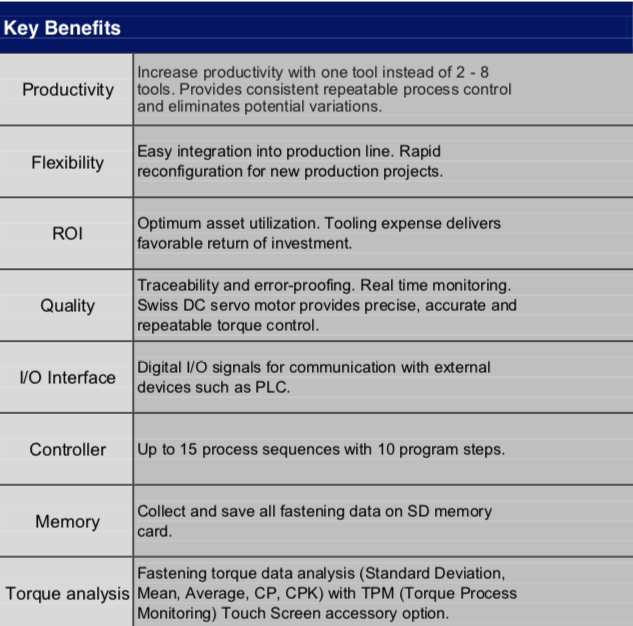

– Productivity – Increase productivity with one tool instead of 2 – 8 tools. Provides consistent repeatable process control and eliminates potential variations.

– Flexibility – Easy integration into production line. Rapid reconfiguration for new production projects.

– ROI: – Optimum asset utilization. Tooling expense delivers favorable return of investment.

– Quality: Traceability and error-proofing. Real time monitoring. Swiss DC servo motor provides precise, accurate and repeatable torque control.

– I/O Interface – Digital I/O signals for communication with external devices such as PLC.

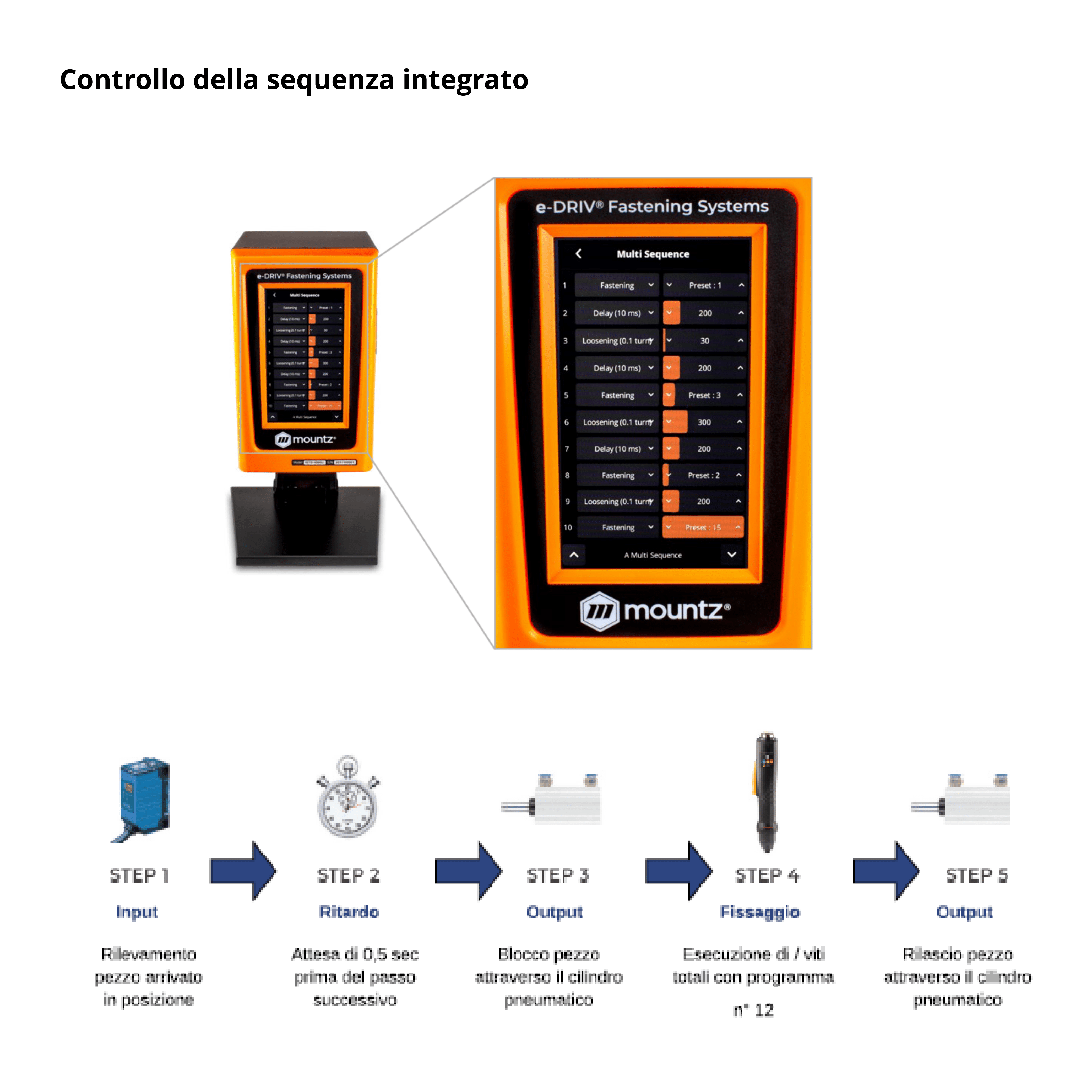

– Controller: – Up to 15 process sequences with 10 program steps.

– Memory: – Collect and save all fastening data on SD memory card.

– Torque Analysis – Fastening torque data analysis (Standard Deviation, Mean, Average, CP, CPK) with TPM (Torque Process Monitoring) Touch Screen accessory option.

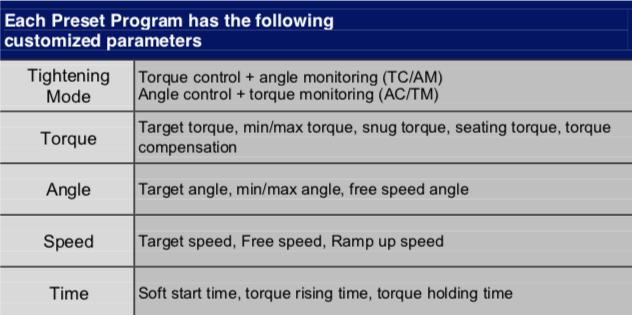

TECHNICAL FETURES:

- Preset selection capability: Front panel or 25P I/O

-Angle Control: 0.1 -10 turns

- -15 Preset Parameters: Torque, Speed, Soft Start & Angle

- Auto detection of connected driver when controller is powered on*

- Error display: Error code display (3 groups)

- Fastening Quality Control: OK/NG monitoring of screw fastening by preset pattern of angle and/or time

- PC based program for parameter settings, monitoring and real time output

- Front panel 4.3”’D3 Color LCD with touch screen

- Communication 1 x RS232C, 1 x Ethernet

- Protocol: Modbus

- SD Card data memory slot (memory card not included).