The strat-up phase of a system or more simply of a tool is for Airtechnology the fundamental moment that demonstrates the proposed solution in a practical and objective way.

There are six passages that during the start-up phases, regardless of the type of system or solution proposed, are always followed and that according to Airtechnology are the fundamental phases for a qualitative management with high added value.

• 1 – Installation

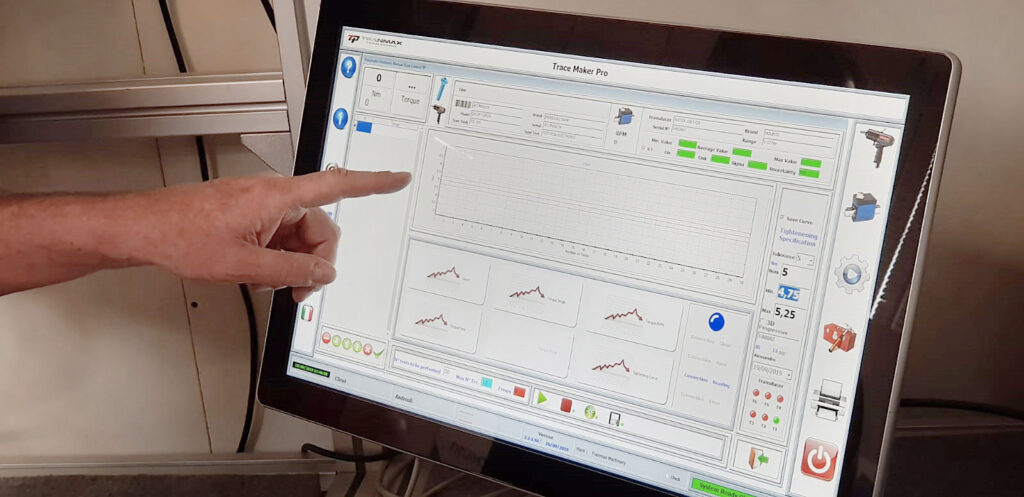

• 2-Programming

• 3-Functional tests

• 4-Backup

• 5-Training and training

• 6-Monitoring of the productivity and efficiency of the plant

The benefits deriving from the application of a start-up carried out effectively and efficiently according to the Airtechnology methods

– Quick and correct initialization of the system

– Proven reduction of risks and delays

– Maintenance and validation of the guarantee

– Control of tool efficiency and ergonomics before commissioning

– Complete support from specialized technicians from the beginning to the end of the process

At the end of the process and before the final release of the solution or the installed tool, the side-by-side production and the analysis of the efficiency of the plant are fundamental factors that allow us to detect any further optimization parameters having as objective the full satisfaction of the customer. Which:

– Additional implementations of tool parameters for increased production efficiency

– Detection of incorrect or non-designed production components that could affect the assembly process.

– Address the correct training and training according to the needs and peculiarities of the personnel in the different roles of use.

For Airtechnology, only through a careful analysis of what is really important for the customer will it be possible to determine the real added value to be brought to implement quality and efficiency in each individual installation installed